Technical insulation

Technical Insulation is our core competence where we, with our long experience, offer professional and high quality solutions in both HVAC and industry.

Our offer

We work with all types of insulation and sheet metal work in both HVAC and industry, at all types of temperatures and applications. We can

- Industrial pipe insulation

- Insulation of tanks and cisterns

- Insulation of boilers

- Insulation of process components

- Pipe insulation

- Ventilation insulation

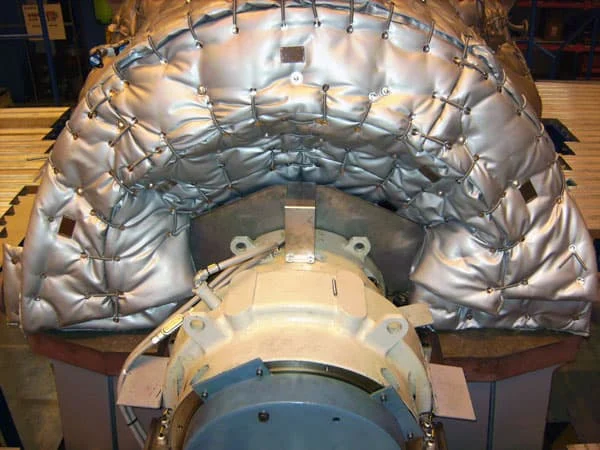

- Mattress manufacturing and mattress insulation

- Sheet metal cladding

- Other specialised missions and applications

insulation material

It is important to use the right insulation material in the right context from a technical, functional and price point of view. We are used to working with all types of insulation materials and applications in both the process industry and HVAC, such as thermal insulation, cold insulation, sound insulation, fire insulation and mattress insulation.

Surface coverings

It is often necessary to have a surface cladding on top of the insulation both for increased durability and any technical requirements, hygiene requirements, external circumstances and not least for aesthetic reasons. We can use all kinds of materials for surface cladding, such as plastic sheet, steel sheet, aluminium sheet, stainless steel sheet, painted sheet, etc. We manufacture the sheet metal parts with great precision in our sheet metal workshop, which is equipped with state-of-the-art machinery for sheet metal processing.

Mattress insulation

We customise mattresses according to our customers' needs and wishes. They are customised to the installation site and offer great advantages in maintenance work as they are easy to dismantle and reassemble for access and servicing of, for example, valves or other process components.

Industry standards

We are used to and familiar with working according to industry standards such as SSG, AMA and industry standards for technical insulation.

AMA has long had standardised insulation series and insulation thicknesses described as a starting point for designers and contractors. Since AMA16, there are no longer any tables for insulation classes and insulation thicknesses described, as they were moved to RA16, and they are not described in AMA19 either.

In spring 2020, IF - Isoleringsfirmornas förening has therefore developed an industry standard for technical insulation, BTI, which covers both heating and ventilation. It introduces the insulation classes R0-R7 for pipes and V0-V6 for ducts.

If you have any questions about this, please do not hesitate to contact us!

![Madrass 2 600x450px[1]](https://thermion.se/wp-content/uploads/2023/12/Madrass-2-600x450px1.webp)

![94434f1a4040b9903019091e9ae10a32[1]](https://thermion.se/wp-content/uploads/2023/12/94434f1a4040b9903019091e9ae10a321.webp)

Benefits of properly executed insulation

Effective heating or cooling insulation provides quick economic benefits. The payback period on investments in technical insulation is surprisingly short and they also provide major environmental benefits where CO2 emissions can be significantly reduced. The choice of insulation material varies according to the nature of the task, the temperature of the medium and the environment, and the location of the installation. This may involve pipe installations, cold rooms, ventilation, refrigeration systems, ships, tank farms, etc.

Frequently asked questions about technical insulation

What is technical insulation?

Technical insulation involves insulating pipes, ducts, tanks and other technical installations to reduce heat and cold losses, prevent condensation, increase energy efficiency and improve safety. It is used in both HVAC and industrial applications.

What types of technical insulation does Thermion offer?

Thermion offers a range of insulation services, including:

Industrial pipe insulation

Insulation of tanks and cisterns

Insulation of boilers

Insulation of process components

Pipe insulation

Ventilation insulation

Mattress manufacturing and mattress insulation

Sheet metal cladding

Customised solutions

Why is technical insulation important?

Proper technical insulation helps:

Reduced energy losses

Improved energy efficiency

Prevention of condensation and corrosion

Increased safety by reducing the risk of burns

Sound attenuation

Fire protection

What materials are used in technical insulation?

The choice of insulation material depends on the application and can include:

Mineral wool

Foam plastic material

Cellular rubber

Ceramic fibres

Customised mattresses

Thermion works with different materials to meet specific needs in both HVAC and industry.

What is mattress insulation?

Mattress insulation involves the use of flexible, removable insulation mattresses that are customised for specific components such as valves, flanges and other irregular shapes. They are easy to assemble and disassemble, facilitating maintenance and inspection.

How does technical insulation affect the environment?

By reducing energy losses, technical insulation contributes to lower energy consumption and thus reduced CO2 emissions. This supports sustainability goals and can lead to significant environmental benefits

Does Thermion work according to industry standards?

Yes, Thermion follows industry standards such as SSG, AMA and Branschstandard Teknisk Isolering (BTI), which ensures high quality and compliance with applicable guidelines.

How can I get a quote for technical insulation?

To get a quote, you can contact Thermion by email at info@thermion.se or call +46 (0) 10 226 32 80. You can also visit our contact page for more information.